MSC Marc是MSC.Software公司于1999年收购的MARC公司的产品。MARC公司始创于1967年,是全球首家非线性有限元软件公司。经过三十余年的不懈努力,MARC软件得到学术界和工业界的大力推崇和广泛应用,建立了它在全球非线性有限元软件行业的领导者地位。随着Marc软件功能的不断扩展,软件的应用领域也从开发初期的核电行业迅速扩展到航空、航天、汽车、造船、铁道、石油化工、能源、电子元件、机械制造、材料工程、土木建筑、医疗器材、冶金工艺和家用电器等,成为许多知名公司和研究机构研发新产品和新技术的必备工具。

MSC MARC 2016为非线性优化分析,提供全面的、健壮的解决方案解决问题方案跨越整个产品寿命,包括制造过程仿真、设计性能分析、服务负载性能和失效分析。

新材料模型既能解决各种新的问题类型又能提高置信度

• Marc 2016 引入了新型材料模型,可仿真弹性体的复杂动态行为、热塑性塑料的永久变形以及金属成型中常见的各向异性塑性变形。

增强粘性接触功能,简化设置且易于使用

• 装配时,通常采用离散的实体(如铆钉、螺栓或点焊接)将零部件连接在一起。对离散实体进行建模往往非常昂贵,因此会假定一个统一的刚体“粘结”。虽然方便 使用,但这种方法通常会导致结构过于刚硬。为克服这一缺陷,Marc 2015 版提供了一种粘性接触行为,使用户能够沿法向和切向采用有限的刚度,从而改善了接触区的应力结果及整体形变。

全新的单元技术可实现高效计算资源应用

• Marc 2016 引入了新的单元系列。与传统的低阶三角形和四面体单元相比,它简单易用,改进了弯曲行为,可用于仿真可压缩或者几乎不可压缩的行为。新单元只需较少的数量就能准确地表征剪切行为,有助于节约系统资源、以较低的成本获得更好的结果。

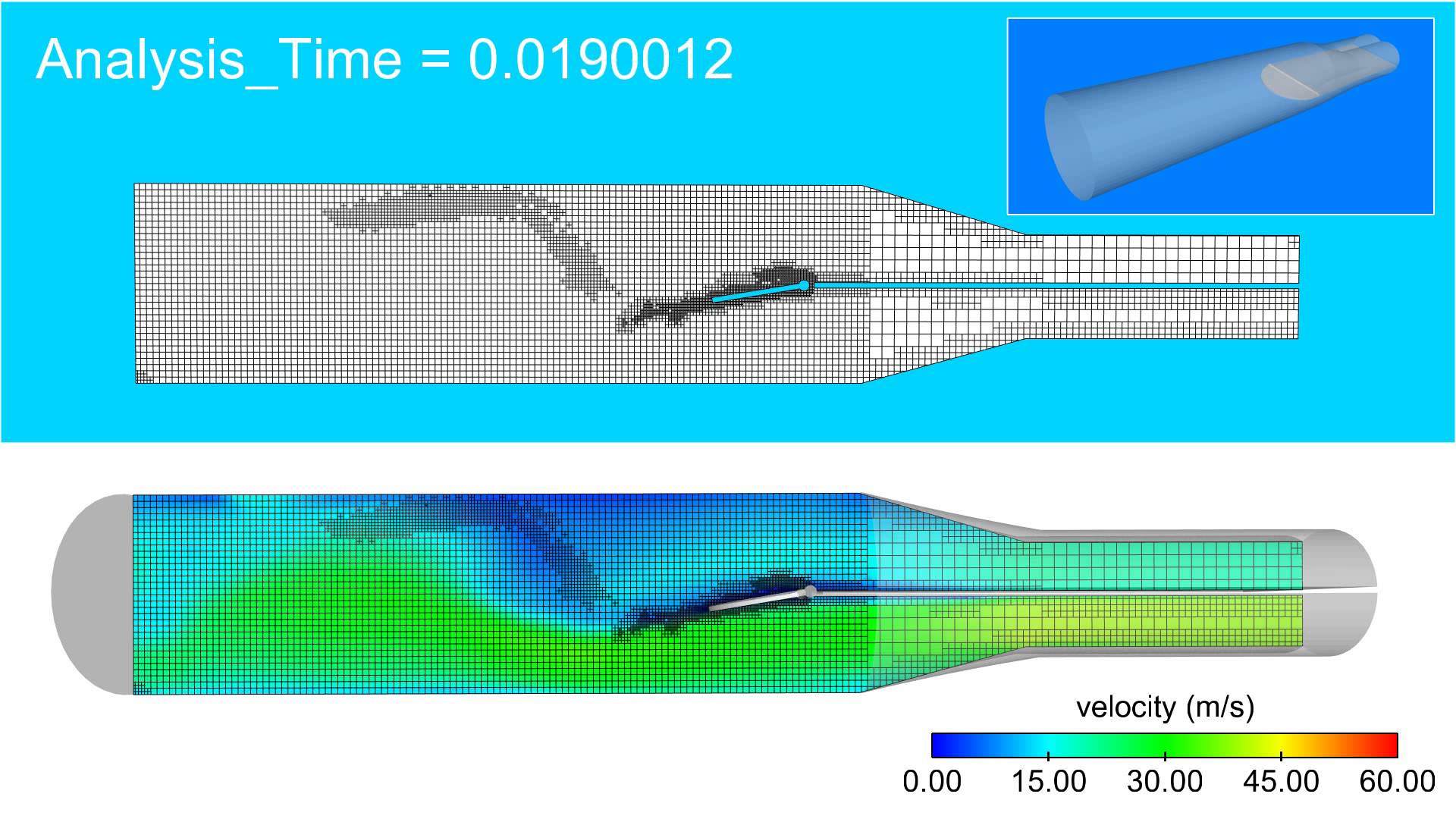

新的全局自适应网格划分方法可提高准确度

• 引入了两种新功能来改进全局自适应网格划分。在运用全局自适应网格划分技术对橡胶零部件和加工问题进行仿真时,新的几何体保存方法可提高准确度。采用在三维裂纹尖端激活的精细模板网格,能够准确地预测能量释放率、应力强度因子及裂纹扩展方向,同时可保持较低的计算成本。

用户界面提升了易用性和效率

• 已对 Marc 的用户界面 Mentat 的若干部分进行了改进,以便于使用、提高生产率。

Marc is a powerful, general-purpose, nonlinear finite element analysis solution to accurately simulate the product behavior under static, dynamic and multi-physics loading scenarios. Marc’s versatility in modeling nonlinear material behaviors and transient environmental conditions makes it ideal to solve your complex design problems.

Marc is ideal for product manufacturers looking for a robust nonlinear solution. It has capabilities to elegantly simulate all kinds of nonlinearities, namely geometric, material and boundary condition nonlinearity, including contact. It is also the only commercial solution that has robust manufacturing simulation and product testing simulation capabilities, with the ability to predict damage, failure and crack propagation. Combined with its multi-physics capabilities that help you couple thermal, electrical, magnetic and structural analyses, Marc is the complete solution that can address all your nonlinear simulation requirements.

Marc, optimized for nonlinear analysis, delivers comprehensive, robust solution schemes to solve problems spanning the entire product lifespan, including manufacturing process simulation, design performance analysis, service load performance and failure analysis.

These include:

– Nonlinear analysis that incorporates all forms of nonlinearities (Material, geometric, boundary condition including contact)

– Thermal analysis

– Coupled thermomechanical analysis

– Electromagnetics

– Piezoelectric analysis

– Electrical-Thermal-Mechanical

– Electrostatics and Magnetostatics coupled with structural response

– Manufacturing processes like sheet metal forming, hydroforming, extrusion, blow molding, welding, quenching, curing, cutting etc.

MSC Marc v2016 x64 注册版- 非线性有限元软件下载地址:

[erphpdown]Download 百度云盘:

http://pan.baidu.com/s/1skUfQOH 密码:pz96

解压密码:www.unyoo.com[/erphpdown]

联合优网

联合优网